Brochure

Download our document to see specific data of the service and how we work.

Let’s Start Work

Together

Please feel free to contact us. We will get back to you with 1-2 business days. Or just call us now.

377 villa, dream city, Erbil, Kurdistan region of Iraq

The penetration grading system was developed in the early 1900s to characterize the consistency of semi-solid asphalts. Penetration grading quantifies the following asphalt concrete characteristics:

Pentration Grade Bitumen is Bitumen classified using the penetration property. Penetration grading’s basic assumption is that the less viscous the asphalt, the deeper the needle will penetrate. Bitumen which is produced during the process of oxidation of vacuum bottom (the Bitumen production feedstock that derives from distillation tower residue in vacuum oil refineries) at bitumen production unit in a manner that its penetration point (kind of test to indicate the hardness of bitumen) in specified group is classified in different grade of Bitumen.

Penetration Grade Bitumen is commonly used in road surfacing, and some industrial applications. Additional processing yields other grades of bitumen products and their application.

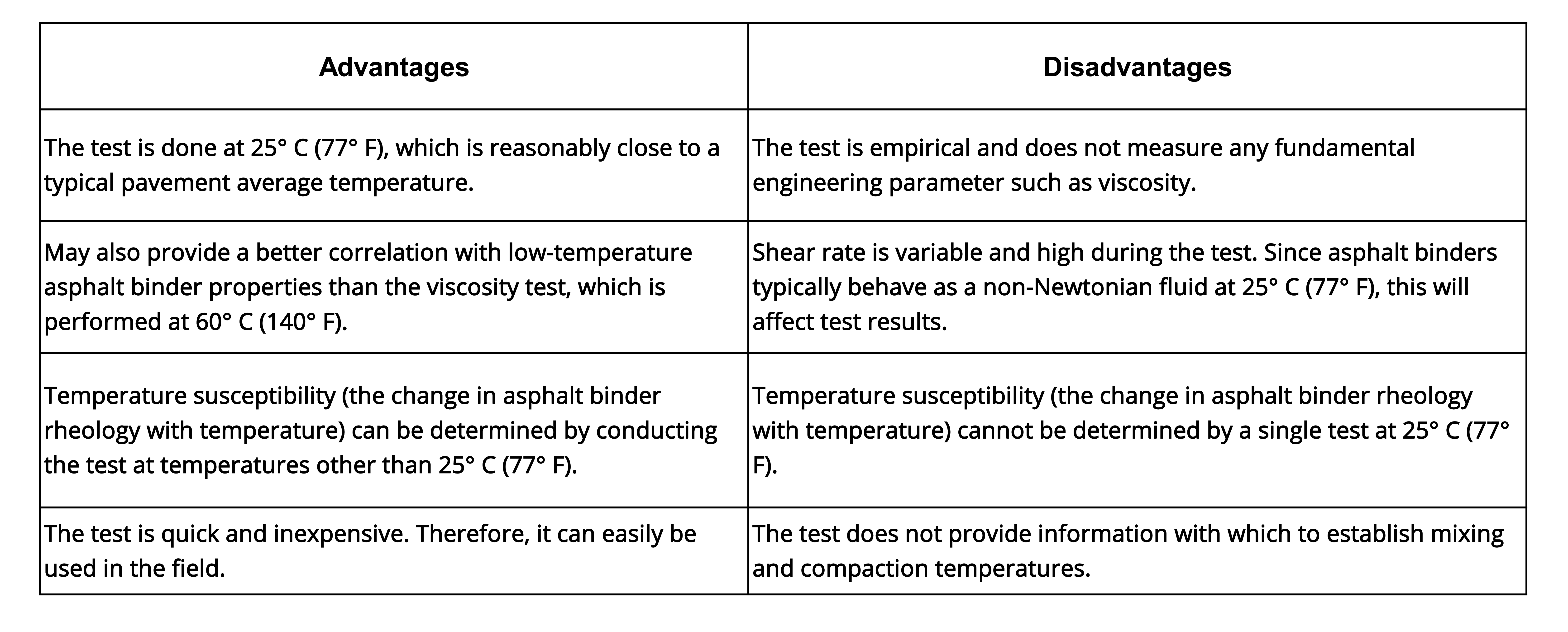

Penetration grading key advantages and disadvantages are listed as below

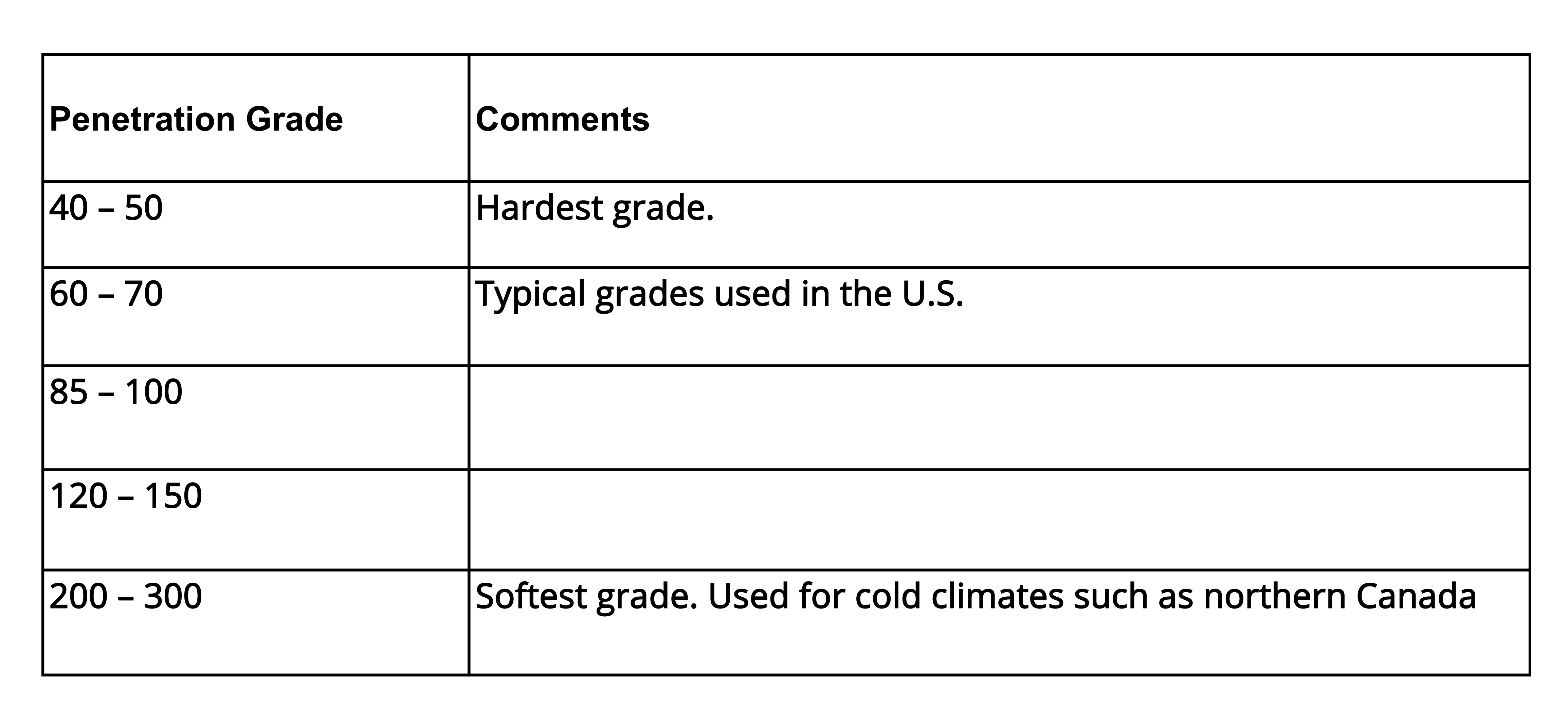

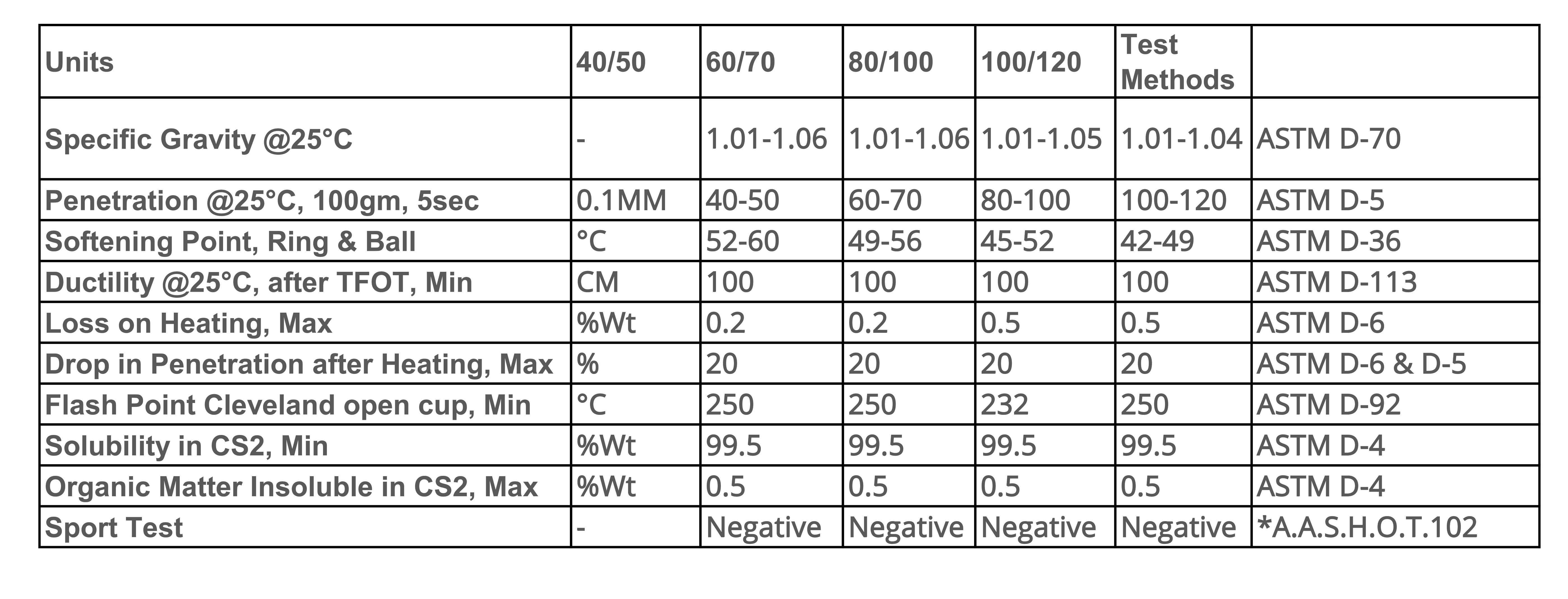

Penetration grades are listed as a range of penetration units (one penetration unit = 0.1 mm) such as 120 – 150. Penetration grades specified in AASHTO M 20 and ASTM D 946 are listed in below table

Penetration Grade Bitumen Specification (AASHTO M 20 and ASTM D 946)

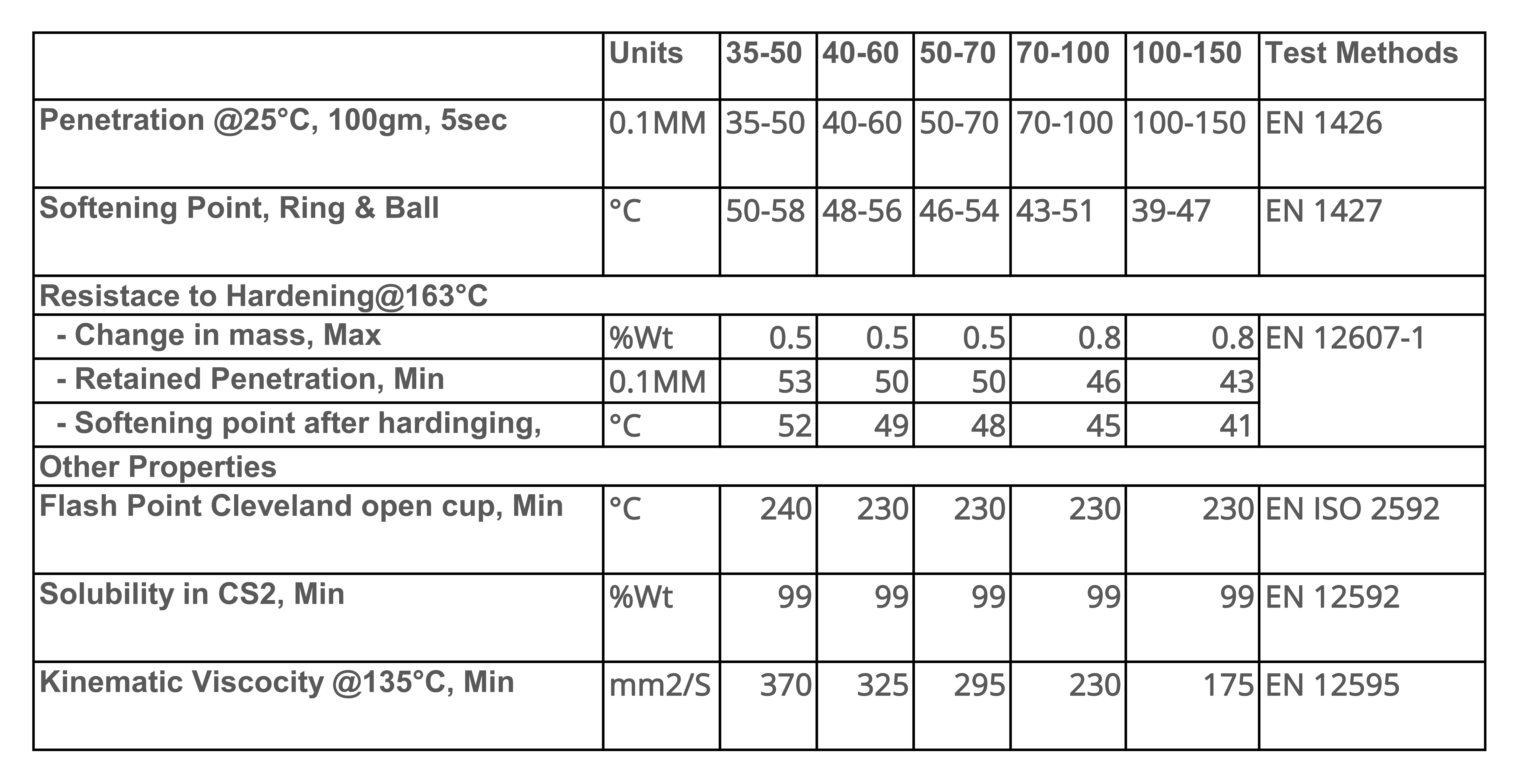

Bitumen Specification European Standard (BS EN 12591)

Bitumen Specification European Standard (BS EN 12591)